In labs and small workshops, a materials shift is changing how backpacks are made and how we think about them.

The numbers show a hidden story: Dyneema® has great strength for its weight. It’s way stronger than steel but weighs less than a cotton t-shirt. This big change makes designers rethink old ideas about outdoor gear.

But Dyneema isn’t the only thing that matters. On July 15, 2025, Dyneema showed a new material way stronger, tougher, and lighter than their normal stuff. Materials like VX21 and Ultra 200 ripstop are also making new kinds of gear possible.

The Materials That Started It

Dyneema Composite Fabric: A Big Deal

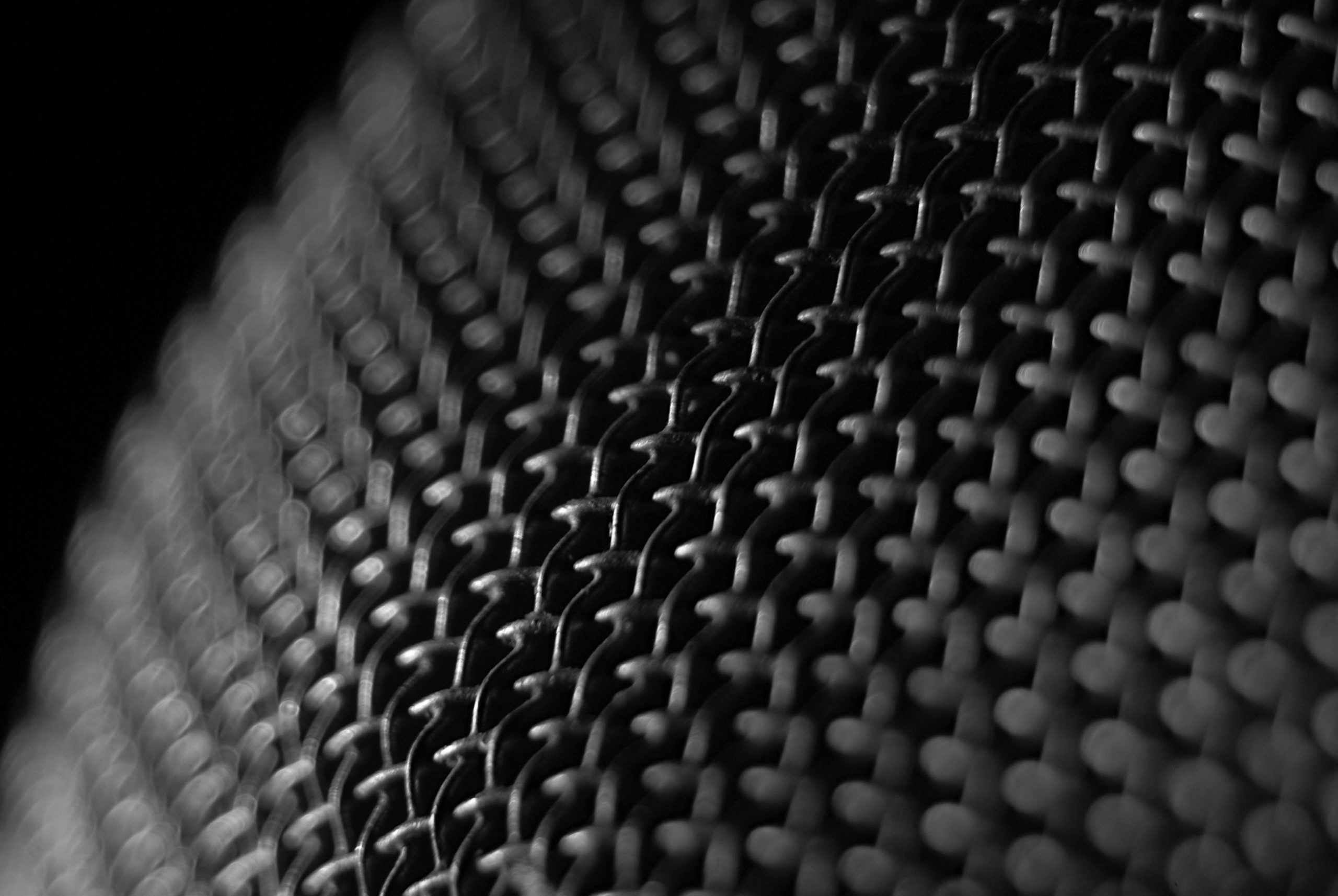

Dyneema® Composite Fabric is a special fabric made from Dyneema fibers. It’s strong, but it also pushes makers to rethink how they build things.

When we used DCF at first, we tried our usual sewing, says Jake Thompson, a product head at a small company. The fabric didn’t work with it. We had to find new ways to sew it, spread out stress, and plan pack size.

DCF is tricky because it’s different. Normal fabrics stretch, but DCF moves stress in ways that can cause problems if you aren’t careful. So, taped seams, special panel designs, and removing some stitches have become common.

VX21: A Good Balance

Ripstop Soft X-Pac VX21 RS™ is softer than Terrain X-Pac™ VX21. The extra ripstop makes it stronger against tears. Many designers think it’s a perfect material for light gear.

DCF fabrics are lighter than VX21, but VX21 is easier to use. It’s made of layers that can handle wear and tear while staying light.

VX21 saved us, says Sarah Chen, who started a gear company. Our DCF packs needed too much care, and we lost customers. VX21 gave us light gear that lasted like people expected.

Ultra 200 Ripstop: A Contender

When Challenge Sailcloth made Ultra fabrics, it gave gear makers another choice besides Dyneema.

UltraGrid™ is better than other pack fabrics of the same weight. It’s cheaper and has nicer colors than UltraWeave™ 200/400 fabric, which is stronger. These materials offer different levels of performance for light gear.

Changing How We Design

From Too Much to Just Enough

Backpack design used to be about using strong materials and extra stitching. That made sense when materials were heavy and weak.

Now, very light fabrics have changed that. Every bit of weight matters, so overdoing it wastes material.

We had to trust the materials, says Maria Rodriguez, a pack designer. One good seam can be better than three old ones. But we had to forget years of being extra safe.

New Ways to Sew

Seams show this change well. Old gear used strong seams and lots of stitching. These worked for thick fabrics.

Light materials need careful work. Dyneema mixes Dyneema fabrics with other fabrics, making a light, strong material. But it needs sewing methods from sailing and plane making.

Taped seams are now normal for light packs. Heat welding is also common. Some makers use machines made for medical gear.

Going Small: Sub-30D Fabrics

What’s Denier?

Denier is how heavy 9,000 meters of fiber is. Old fabrics are 70D to 1000D+. Sub-30D fabrics are much different and need changes to:

- Thread: Normal thread can be heavier than the fabric.

- Needles: Needles make holes that are too big.

- Stitches: Too many stitches make weak spots.

- Seam size: Big seams add extra weight.

Hard to Make

It’s not hard to use these materials for prototypes, says David Park, a production manager. It’s hard to make lots of them and keep the quality. One wrong stitch can ruin everything.

This has changed the industry. Some companies bought special machines and training. Others stopped using light materials.

Examples

Hyperlite Mountain Gear: A Leader

Hyperlite Mountain Gear uses Dyneema a lot.

Their packs have few seams and use Dyneema’s strength well. They pick parts that work with the material.

ULA Equipment: A Careful Choice

ULA Equipment offers different materials and talks about the pros and cons.

Vaucluse Gear: A Small Innovator

Vaucluse Gear’s backpacks show what small companies can do. Their light backpack is very light, which wasn’t possible before.

Why Some Say No

Too Hard

Not everyone uses light materials. Some big brands are slow to change because of the cost.

It costs a lot to use these materials right, says a product manager. New machines, training, quality control, and customer education are needed. It’s a big risk for a company that ships lots of products.

Not Tough Enough?

Old gear was made to last. Some worry that light materials will cause problems and returns.

We’re known for packs that last, says a design director. These materials might be better, but we don’t know how they’ll hold up. What if a pack breaks in the wild?

Not Many Buyers

Light materials are a small part of the market. Most people want cheap, familiar gear.

Light gear users are loud, but they’re a small group, says a brand manager. Most buyers want a normal pack under $150 that can handle being thrown around.

Is It Green?

What About the Earth?

Light materials have good and bad points for the environment. They can last longer, which is good.

But making these materials uses a lot of energy and chemicals. We don’t know the full impact because they haven’t been used long enough.

Hard to Fix

Old gear is easy to fix. Light materials need special repairs and sometimes factory service.

We make great products that might not be easy to fix, says a sustainability director.

New Ways to Build

Lasers

Old cutting used stencils and blades, which wasted fabric. Now, lasers cut shapes with less waste.

Lasers let us make patterns that reduce stress, says a designer. We can make every curve perfect for light materials.

Bonding

Sewing is being replaced by:

- Heat welding: Making waterproof seams without holes

- Ultrasonic welding: Joining materials together

- Adhesive taping: Strengthening weak spots

- Mixing methods: Using sewing and bonding

Smarter Designs

Some makers use computers to plan material use. Every part is checked for strength and weight.

We can see how stress moves across the pack and put material where it’s needed, says an engineer. We don’t have to overdo it everywhere.

What’s Next?

New Dyneema

The new Dyneema is better than the old one.

It’s easier to handle and performs well. This could make more companies use it.

Green Options

Research into plant-based materials is growing because of environmental worries. They aren’t as good as synthetic ones yet, but they’re getting closer.

Smart Materials

Future materials might have sensors, heal themselves, or adapt to conditions. These could change how packs work.

What It Means for You

Know the Trade-offs

Light materials need different care:

- Careful packing: Protect from sharp objects

- Different cleaning: Don’t wash like normal

- Harder repairs: Need special skills

- Costs: More money at first, but might last longer

Pick the Right Material

Match the material to how you use it:

- DCF: Best for saving weight if you don’t mind being careful

- VX21: Good for light weight and lasting a while

- Ultra fabrics: A good middle ground

- Mixing materials: Using the best material in each spot

How It Changes Things

Supply Chain

The light gear shift is changing the supply chain:

- Special suppliers: New companies focus on advanced materials

- New machines: Companies buy precise cutting and bonding tools

- Better testing: New ways to check how materials break

- Different storage: Special needs for storing materials

Skills

There aren’t enough people with the right skills. Companies are training staff or working with specialists.

More Innovation

Light materials have pushed innovation across the industry. Methods made for light gear are being used in normal products.

The Future

Normal Now?

Light materials might get cheaper and easier to find. This could make them more common.

Working Together

The challenge is using light gear with other gear. A light pack isn’t much help if the rest of your stuff is heavy.

A New Mindset

The biggest change might be thinking about just enough instead of too much. This changes how we think about gear.

People Matter

Designers

These materials have made me a better designer, says Jamie Chen. You can’t just add more material to fix problems. You have to think about every choice.

Users

Hikers are changing how they pack and care for gear.

Community

The light gear community shares tips about materials and building methods. This helps the gear get better.

In Conclusion

The change in backpack design is about materials and a new way of thinking. Now, packs can be very light and still handle tough trips.

This change isn’t over. As materials and methods improve, we’ll see even bigger changes. Light gear ideas might become normal, pushing even old companies to change.

This means better, lighter gear for you that might last longer. But it also means learning new care tips and paying more at first.

The quiet shift is easy to hear if you listen closely. The soft sound of a DCF bag, the light rustle of VX21, and the click of buckles show that things are changing.

The future of backpacks is lighter, smarter, more precise, and more thoughtful. It’s happening now, one seam at a time.

#UltralightBackpacking #DyneemaComposite #PackDesign #UltralightMaterials #BackpackInnovation #TechnicalFabrics #UltralightGear #VX21 #DCF #OutdoorGearTech #MaterialScience #BackpackEngineering #UltralightRevolution #GearInnovation #OutdoorIndustry